Computerized embroidery machines are a product of modern technological advancements, capable of replacing the majority of manual embroidery work. They offer several advantages, including stable quality, high efficiency, low cost, and the ability to produce in bulk. The main functional performance of an embroidery machine is determined by factors such as the number of heads, head spacing, needle count, the large travel range of the embroidery frame in the X and Y directions, the electronic control system, and the manufacturer’s brand.

The number of heads refers to the number of machine heads working simultaneously during embroidery, which determines the efficiency of the machine. Head spacing is the distance between two adjacent machine heads, which determines the size and cost of individual or cyclical embroidery on the machine. The needle count is the number of single needles installed on each head of the embroidery machine, which determines the maximum number of color changes and the variety of colors in the embroidered product. The large travel range of the embroidery frame in the X and Y directions determines the size of the embroidered product that the machine can produce. Different manufacturers and brands correspond to different qualities, services, and professional embroidery machines.

Classification of Computerized Embroidery Techniques

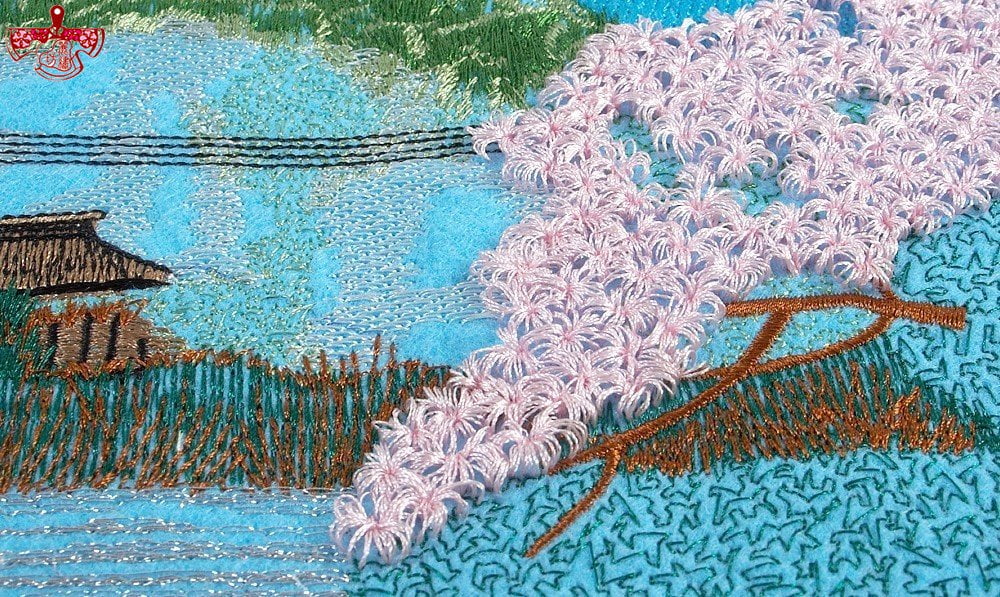

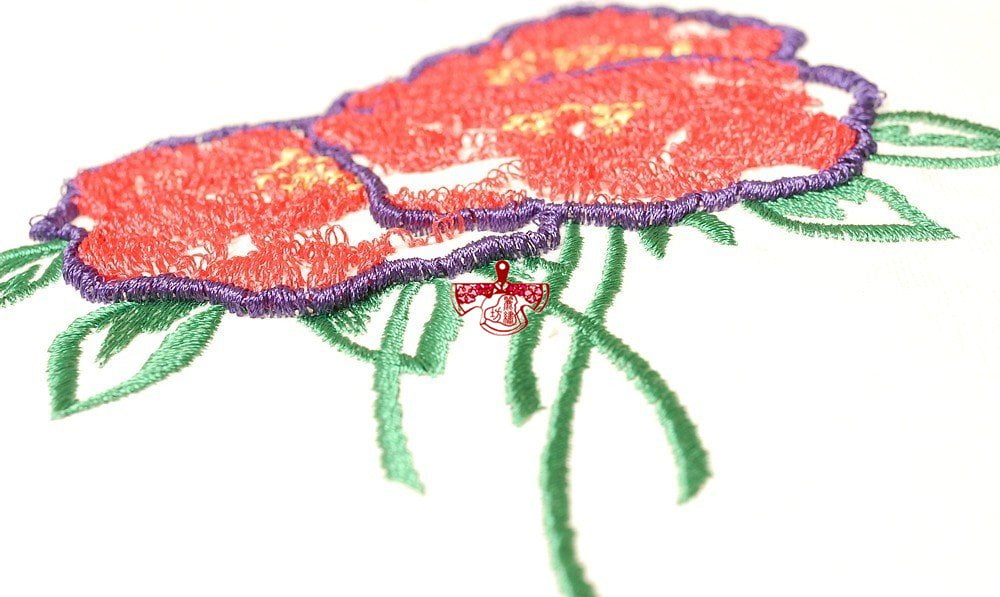

- Plain Embroidery

Plain embroidery is the most widely used embroidery technique and can be applied to any material that is suitable for embroidery.

2. 3D Embroidery

3D embroidery utilizes embroidery threads to envelop EVA foam, creating a three-dimensional pattern. It can be produced on top of regular flat embroidery. (EVA foam comes in various thicknesses, hardness, and colors.)

3. Hollow 3D Embroidery

Hollow 3D embroidery can be produced on regular flat embroidery and uses a method similar to 3D embroidery with foam. After embroidery is completed, the foam is washed away using a dry cleaner to form a hollow center. (The foam surface is smooth, and the typical thickness ranges from 1 to 5mm.)

4. Applique Embroidery

Applique embroidery uses applique to replace stitches, saving embroidery thread and making the pattern more vivid. It can be produced on a regular flat embroidery machine.

5. Thick Thread Embroidery

Thick thread embroidery uses thicker sewing threads (such as size 603) as embroidery threads, in conjunction with large-hole needles or large needles, thick thread shuttles, and a 3mm needle plate to complete the embroidery. It can be produced on a regular flat embroidery machine.

6. Cutwork Embroidery

Cutwork embroidery can be produced on a regular flat embroidery machine but requires the installation of a cutwork embroidery attachment (currently, it can only be installed on the first needle bar). It uses a cutting tool to pierce the fabric and then embroiders the edges with embroidery threads to form a perforated pattern in the middle.

7. Flat Gold Thread Embroidery

Flat gold thread can be used on a regular flat embroidery machine for production, but a flat gold thread attachment is required (it can be installed on any needle bar).

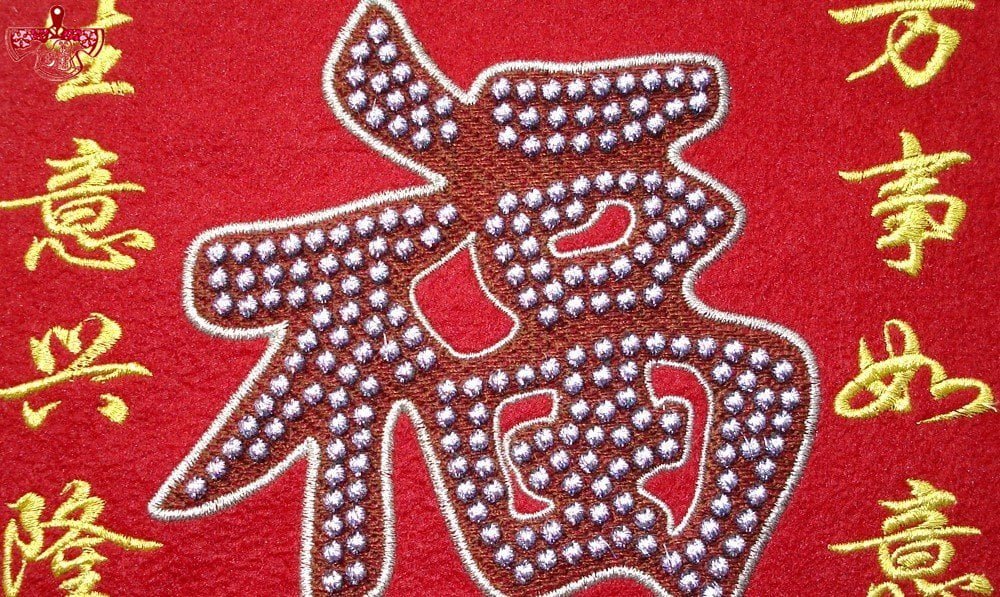

8. Bead Embroidery

Bead embroidery involves stringing beads of a specified shape and size into a rope-like material, which is then embroidered on a flat embroidery machine equipped with a bead embroidery attachment.

Note: A bead embroidery attachment is required.

The bead embroidery attachment can be installed on the first needle or the last needle of a designated machine head to perform innovative bead embroidery. It can accommodate bead specifications ranging from 2MM to 12MM.

9. Flocking Embroidery

Flocking embroidery can be produced on a regular flat embroidery machine but requires the installation of a flocking needle. The principle of embroidery is to use the hook on the flocking needle to lift the fibers from the flocking fabric and implant them onto another fabric.

10. Toothbrush Embroidery

Also known as standing line embroidery, toothbrush embroidery can be produced on a regular flat embroidery machine. The embroidery method is the same as 3D embroidery, but after the embroidery is completed, a portion of the plastic film must be cut away, and then the entire plastic film must be removed, allowing the embroidery threads to stand upright.

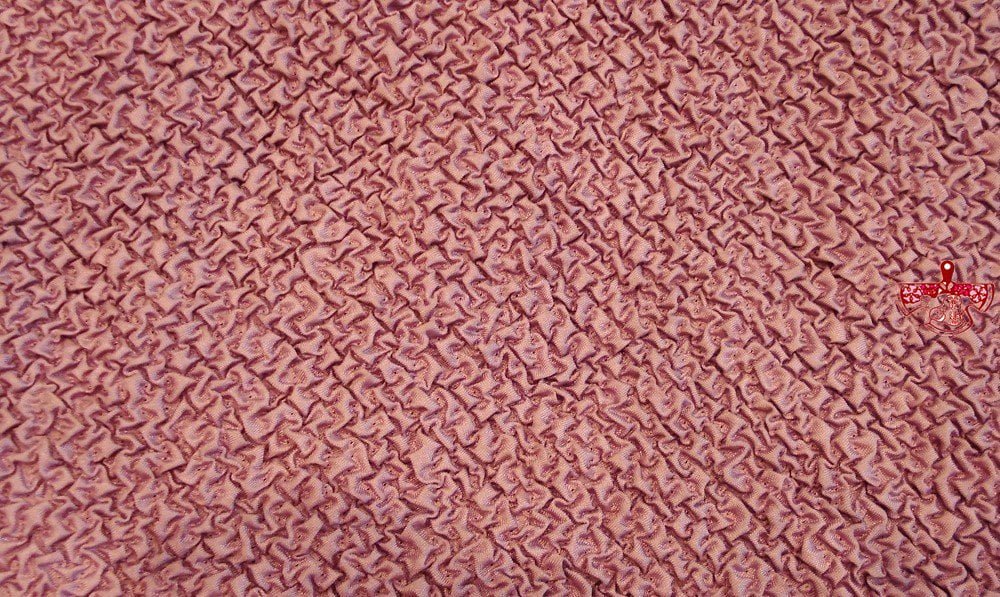

11. Pucker Embroidery

Pucker embroidery can be produced on a regular flat embroidery machine but requires the use of a shrinkable backing and water-soluble bottom thread. After the embroidery is completed, the fabric is puckered by the shrinkable backing when heated. When the water-soluble bottom thread is dissolved in water, the backing can be separated from the fabric. However, it is important to note that synthetic thin fabrics should be used for a more pronounced effect.

12. Finished Cap Embroidery

Finished cap embroidery requires a tubular machine with a cap frame to produce. It is a method of embroidering after the cap has been made into a finished product.

13. Garment Embroidery

Garment embroidery requires a tubular machine with a garment frame to produce. It is a method of embroidering after the finished garment has been placed on the machine.

14. Sock Embroidery

Sock embroidery can be produced on a regular flat embroidery machine but requires a sock frame for embroidery.

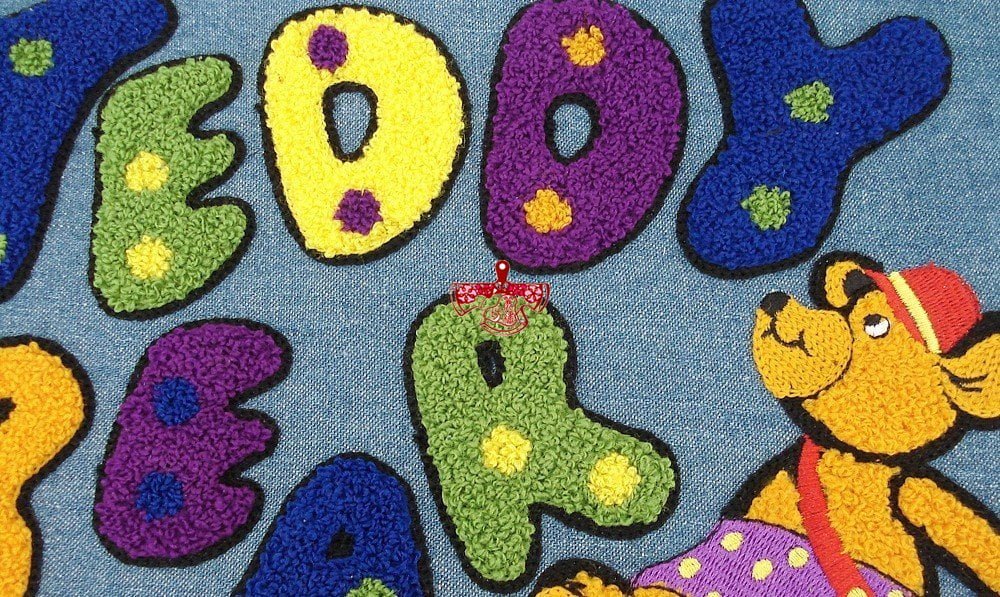

15. Chain Stitch + Towel Embroidery

Towel embroidery is a very popular embroidery method on European and American clothing. The effect is like attaching a piece of terry cloth, with a soft touch and a variety of color changes. During embroidery, a special towel machine head is used to hook up the ordinary embroidery thread from the bottom of the machine, forming a loop after another to create a towel effect.

16. Link Stitch

Also widely popular in Europe and America, this embroidery technique is completed by changing the special machine head’s hooking action. Since the loops are linked one after another, forming a chain-like shape, it is named accordingly. Due to its unique effect, it is a very profitable embroidery method.

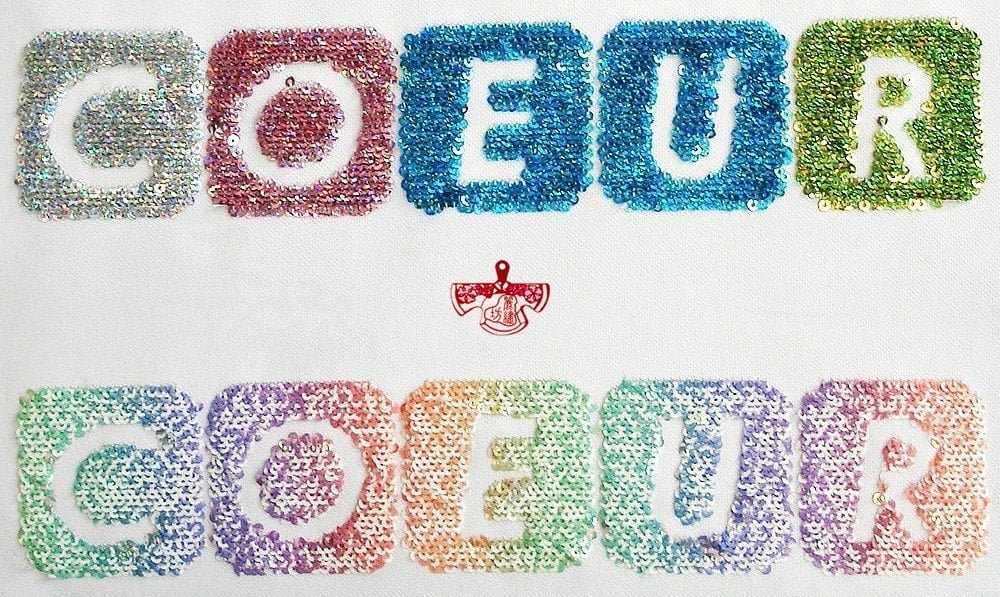

17. Crystal Embroidery

Using automated machines to set Swarovski crystals and various colored crystals, it adds a more luxurious and fashionable rhythm to creativity. Requires the embroidery machine to be equipped with a crystal embroidery attachment.

18. Gemstone Embroidery

Gemstone embroidery uses flat gold thread embroidery and 3D embroidery to develop a new process with more variations than imitation stone patches – gemstone embroidery. Note: Special materials are required.

19. High-Speed Rope Embroidery · Imitation Towel Embroidery

A regular flat embroidery machine, with the installation of a high-speed rope embroidery · imitation towel embroidery attachment, can produce this high added-value rope embroidery or imitation towel embroidery products.

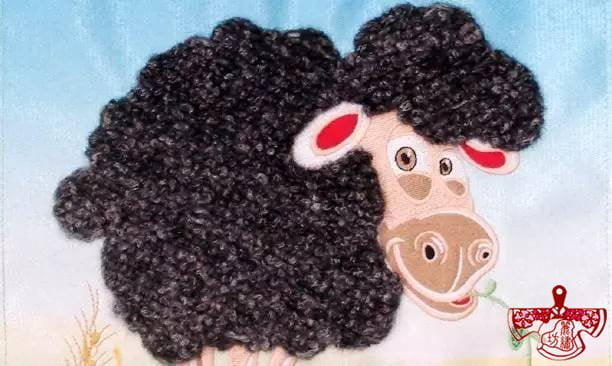

Rope embroidery makes the lines more clear and prominent, without losing softness, adding a full and thick feeling to the embroidery pattern, which is loved by designers and commonly used in clothing embroidery, bag embroidery, home furnishing embroidery, etc.

Imitation towel embroidery is similar to the special machine’s towel embroidery effect, relatively speaking, it has a stronger sense of fluffiness, soft and warm and friendly, and is more used in children’s clothing embroidery, toy embroidery, winter clothing embroidery, etc.

Note: Requires the configuration of a high-speed rope embroidery · imitation towel embroidery attachment.

20. Roll Embroidery

Roll embroidery is a type of embroidery that uses embroidery threads to roll and wrap fine ropes inside.

The three types of threads – embroidery thread, core thread, and roll thread – are integrated to create roll embroidery.

And the interval of the roll can be set in four stages on the control panel, so it can create a rich and colorful, high added-value embroidery product.

21. Concealed Embroidery

Concealed embroidery uses the application of ribbon embroidery, with a special attachment to fix the inner side (lower side) of the ribbon material, without seeing the fixing thread.

The difference between concealed embroidery and ribbon embroidery is that in concealed embroidery, the embroidery thread is pressed under the ribbon, and the embroidery thread is not visible from the surface, while in ribbon embroidery, the fixing thread of the ribbon can be directly seen.

22. Thick and Thin Rope Embroidery

Breaking through the limitations of previous production, it can embroider with a rope of varying thickness. On sweaters and knitted fabrics, it can create a special handicraft embroidery effect. Requires a special guide mouth.

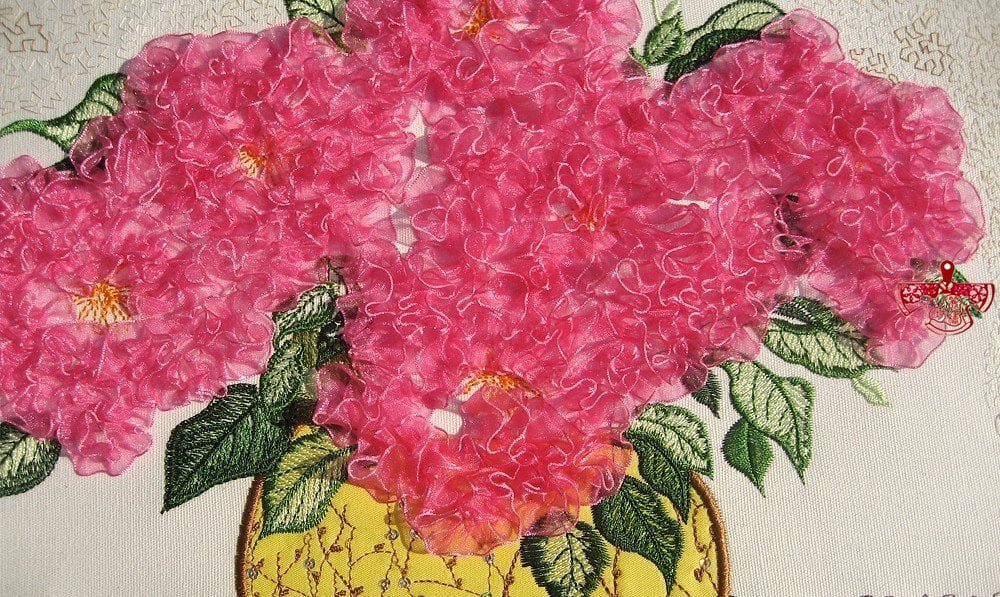

23. Ruffle Embroidery

Ruffle embroidery, also known as feather stitch embroidery, is a method where the ribbon material is repeatedly fixed by the up and down movement of the tube feet when there are feather-like stitches.

24. Zigzag Embroidery

Zigzag embroidery technique is achieved by the left and right swinging of the zigzag embroidery device, taking a left and right lock stitch on the material in a zigzag stitch. There are a total of 6 embroidery stitch options available.

It can also be simply embroidered on materials with creative lines of varying thicknesses and materials that cannot be embroidered directly with a needle.

25. Laser Cutting Embroidery

Laser cutting embroidery can be produced on TLFD, which combines embroidery with laser technology. Laser cutting is divided into surface cutting, semi-cutting, and full cutting.

26. Heat Transfer + Embroidery

This embroidery method combines printing with embroidery, bringing out a unique sense of hierarchy and expressing delicate color patterns through the printed pattern. The advantage is that the pigment is more environmentally friendly, not easy to fade, and there is no need for the traditional printing process of washing before and after dyeing. However, the cost is more expensive than traditional printing. Special materials and special processes are required. The combination of embroidery and printing.

27. Wide Band Embroidery

Wide band embroidery with widths ranging from 30mm to 50mm creates a vertical, three-dimensional effect, often used in high-end evening gowns, wedding dresses, and other women’s apparel.

28. 3D Embroidery

The 3D rope embroidery and ribbon 3D embroidery are similar in technique, but they use rope material, which also creates a layered, uniform three-dimensional effect. Different materials present varying visual outcomes.

29. Delicate Thread Roll Embroidery

Utilizing three types of materials: embroidery thread (75d/2), core thread (300d/2), and roll thread (two strands of 75d/2), the embroidery process envelops the core thread with the roll thread. The ratio of roll thread to core thread can be selected from four options, enabling the creation of rich and colorful, high-value-added embroidery products. A fine thread roll embroidery attachment is required.