SEWING NEEDLE

Many people have the question about how to select the correct needle size? In fact the relationship between needle and thread is crucial to successful sewing or quilting. As important as it is to select the proper needle for the fabric, it is equally important to select the proper needle for the thread you are using. Very often thread breakage, skipped stitches or other “thread” problems are the result of damaged or improper needle selection.

Selecting the proper machine needle

Proper needle selection is determined by two key factors: 1) the thread to be used and 2) the fabric to be sewn or quilted.

• Select the thread to match the fabric or the project

• Next, select the needle type best suited for the fabric used

• Finally, select the needle size to match the thread. The thread must lay in the front groove without sitting on top or wobbling in the groove. 11 The eye must be large enough for the thread to pass through with minimal friction in order to create a perfect stitch.

• Always start with a new needle

Machine Needles

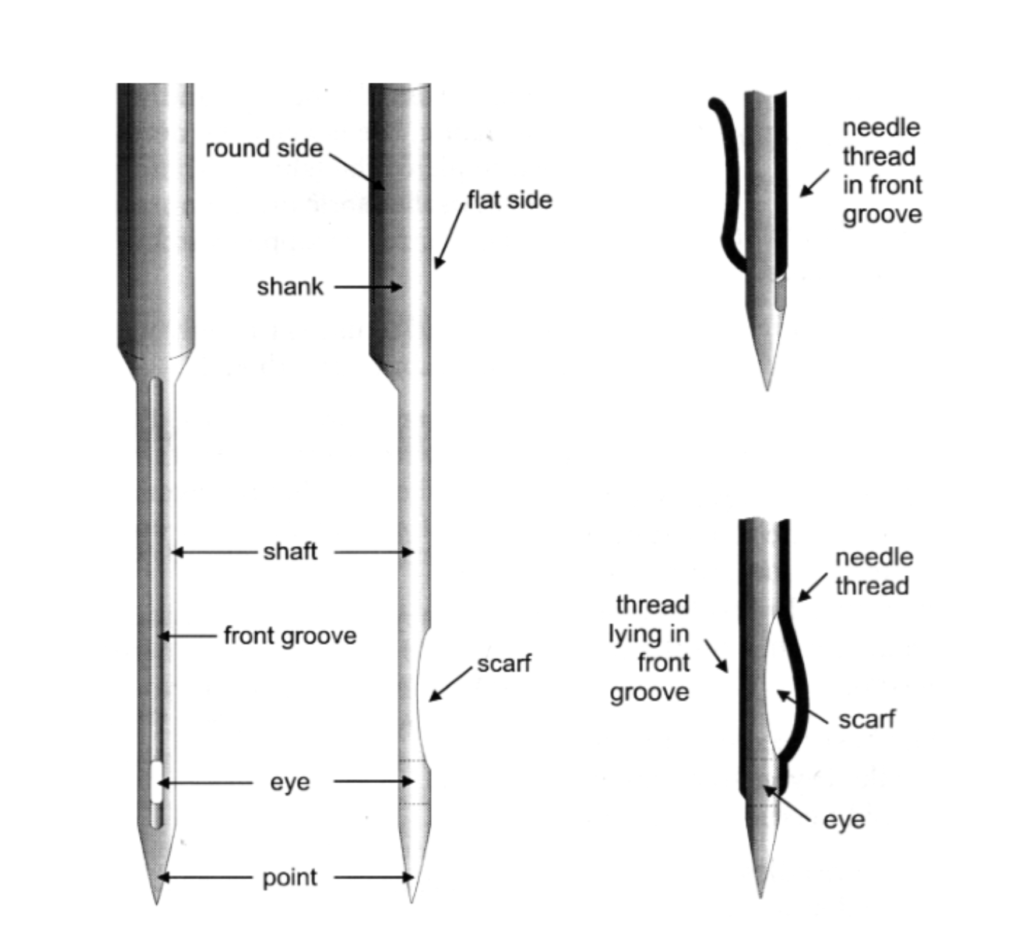

Parts of Machine Needles (Illustration above)

• Point – One of the main differences between needles is the type of point. The point type is the most important consideration in regards to the fabric you will be using.

• Eye – The eye is the hole through which the thread passes and is therefore extremely important to thread selection.

• Shank – This is the part that is inserted into the machine.

• Shaft – The body of the needle itself or how thick the needle is.

• Scarf – This is the indentation in the back of the needle. Important because this is where the stitch is formed. When the bobbin shuttle swings into the scarf it hooks into the looped needle thread to form the stitch.

• Front Groove – The front groove allows the needle thread to lay close to the needle as it travels down the needle towards the bobbin. The deep groove of some needles helps protect the thread from friction created when the needle pierces the fabric. If the needle is too fine for the thread being used, stitch faults may occur.

Machine needles range in size from 60/8 (very fine) to 120/19 (heavy duty). The higher number relates to the needle’s shaft diameter in metric, the lower number to a U.S. system, which also relates to shaft diameter.

• Universal – A general-purpose needle that can be used on woven fabrics as well as knits. They come in 60/8 to 120/18.

• Jeans / Denim – Designed for densely woven and heavily finished fabrics. It features a very stiff shaft, sharp point and slender eye. It is a 12 great choice for getting perfectly straight stitches. Sizes range from 70/10 to 110/18.

• Jersey / Ballpoint – This needle is designed to be used on knits. Its rounded point slips between the fibers rather than cutting them. From 70/10 to 120/18.

• Stretch – This needle has a slightly more rounded point than a universal needle. There is a tiny hump between the eye and scarf that allows the thread to make a large loop on one side of the needle. This loop makes it easy to complete a stitch. They come in sizes 75/11 or 90/14.

• Quilting – These needles have a thin, tapered deep point, which is good for sewing multiple layers. They come in sizes 75/11 or 90/14.

• Microtex – With a thin shaft, and a slim, sharp point, these needles are the right choice for lightweight fabrics, delicate wovens and any heirloom sewing. Sizes range from 60/8 to 100/16.

• Topstitch – This extra sharp needle is less rounded than the universal. The eye is twice as long and the front grove is deeper. This is a good choice when using heavier threads without piercing large holes in the fabric. Sizes 70/10 to 100/16.

• Embroidery – Designed to work with embroidery threads, this needle has a large eye and a special scarf that protects more fragile threads. Sizes range from 75/11 to 90/14.

• Metallica – These needles are designed specifically for metallic and flat decorative threads. The eye is double-sized and Teflon coated, the front groove is deep and the scarf is longer. Sizes 80/12 or 90/14.

Thread/Machine Needle Chart

| Spun Thread | Tex | Needle Selection |

| 70/2 ply | Tex 16 | Universal 70/10, Embroidery 75/11, Microtex 70/10 |

| 60/2 ply | Tex 18 | Universal 70/10, Embroidery 75/11, Microtex 70/11 |

| 50/3 ply | Tex 35 | Universal 70/10 – 80/12, Jeans 80/12, Quilting 75/11 |

| 40/2 ply | Tex 27 | Universal 70/10 – 80/12, Quilting 75/11 |

| 40/3 ply | Tex 40 | Universal 80/12, Sharp 80/12, Embroidery 90/14 |

| 30/2 ply | Tex 35 | Top Stitch 90/14, Embroidery 80/12, Jeans 90/14 |

| 30/3 ply | Tex 50 | Top Stitch 90/14, Quilting 90/14, Embroidery 90/14 |

| Jeans Stitch | Tex 90 | Denim 90/14, 100/16, Embroidery 90/14 |

| Synthetic Thread | Tex | Needle Selection |

| Rayon # 40 | Tex 24 | Embroidery 75/11-80/12 |

| Poly #40 | Tex 24 | Embroidery 75/11-80/12 |

| Rayon/Poly #30 | Tex 40 | Embroidery 90/14 |

| Metallic | Tex 24 | 24 Metallica or Metafil 80/12, Embroidery 90/14 |

| Filament Silk | Tex | Needle Selection |

| #100 | Tex 12 | Microtex 70/11, Embroidery 75/11 |

| #50 | Tex 27 | Universal 80/12, Embroidery 80/12 -90/14 |

| #30 | Tex 60 | Top Stitch 90/14, Embroidery 90/14 |

Hand Sewing Needles

Unlike machine needles, hand needle sizes are backwards: the higher the number the smaller the diameter and the shorter the length.

• Basting – This needle is curved to make basting and tying quilts easy.

• Beading – These are very long with a small eye. They range in size from 10 to 15.

• Chenille / Silk Ribbon – With large eyes and sharp points these are often used for silk ribbon embroidery Sizes range from 18 to 24. 14

• Crewel – These have a sharp point with a long narrow eye. They are used with embroidery floss, silk ribbon and heavier fabrics. Size 1 to 10.

• Darning – These are large needles with very large eyes. Wool darners are used when working with heavy fibers, wide ribbons and wool darning yarns. Sizes 14 to 19 for wool – 1 to 9 for cotton.

• Majestic 88 – These are English needles with a special coating allowing easy stitching through cotton batting or difficult – to – needle fabrics. Sizes 9, 10, & 12.

• Milliners – These are long, narrow needles with a small round eye. They are used in Baltimore Applique, as well as sewing beads and French knots. They range in size from 3 to 9.

• Betweens – These short, fine needles with large eyes are most frequently associated with quilting, but are also used for fine hand sewing. Sizes 3 to 12.

• Sharps – Fine, medium length needles most commonly used for hand sewing and are also used in fine hand embroidery. They range in size from 5 to 12.

• Tapestry – These are stout needles with a long eye and a blunt point. They are used for pulled and drawn work and silk ribbon embroidery. Sizes 13 to 28.

Totally, when using a general-purpose 40-weight thread, you have the choice of using a #60/8, #65/9, or #75/11 needle. The best rule of thumb would be to use the smallest needle with which you are comfortable. This is because the smaller the needle, the smaller the penetration holes will be, and the smaller penetration holes will deliver a crisp, better look to your design. Sometimes a large eye needle will allow you enough flexibility that you can go down a needle size and not struggle with threading your needles. For those new to embroidery, feel free to start with the #75/11 and work down to a smaller one as your comfort level grows, and your technique improves.

When using a thinner 60-weight thread for small lettering or fine detail, a #65/9 needle is a good choice; and when using 75-weight thread, even thinner than 60-weight, a #60/8 needle is suggested. Remember that as the thread weight gets higher, and the thickness decreases, a smaller needle should be used.

Conversely, as the thread weight is assigned a lower number, and the thickness increases, a larger needle must be used. For example, a 30-weight thread would run well with either a #75/11 or an #80/12 needle. Even thicker, a 12-weight thread requires a large #100/16 needle.

As a general rule, the smallest size needle suggested for each thread weight will provide the crispest design. Also, don’t forget to keep in mind the fabric you are using. Ballpoint needles should be used with knits to keep them from “running” and light woven materials, while Sharp needles are best for piercing through structured caps and heavy woven fabrics.